blueover's story #02 About leather

|

ZUCCO Blueover's sample craftsman. He creates shoes by hand, from making patterns to sewing and shoemaking. He also arranges for factories and materials. @blueover_zucco |

This series is a compilation of several posts I wrote on Note in an attempt to explain my work - that is, making shoes - in as easy-to-understand a way as possible.

<When purchasing leather>

I fell in love with leather when I first purchased a leather product in high school. Since I started working in the shoe industry, I have been using leather, and it has become a very familiar part of my work. There are two main options when it comes to where to buy leather.

- Leather wholesaler

- Leather tanner

Type 1 can often be found in Asakusa in Tokyo and Daikokucho in Osaka. They purchase leather from leather tanners all over Japan and overseas, hold inventory, and sell it wholesale. They work with the tanners to create standard products, prepare sample books, and sell them to companies and individuals like us who want leather. Since the wholesaler holds inventory, it is often possible to purchase just one piece.

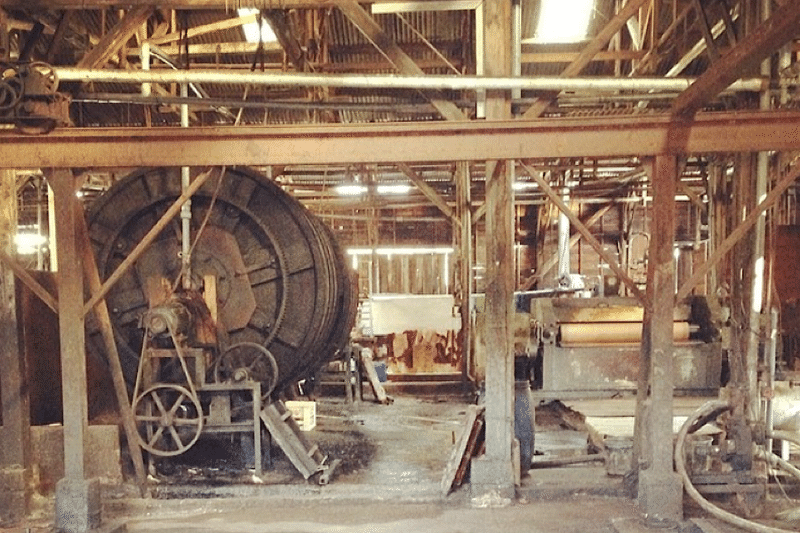

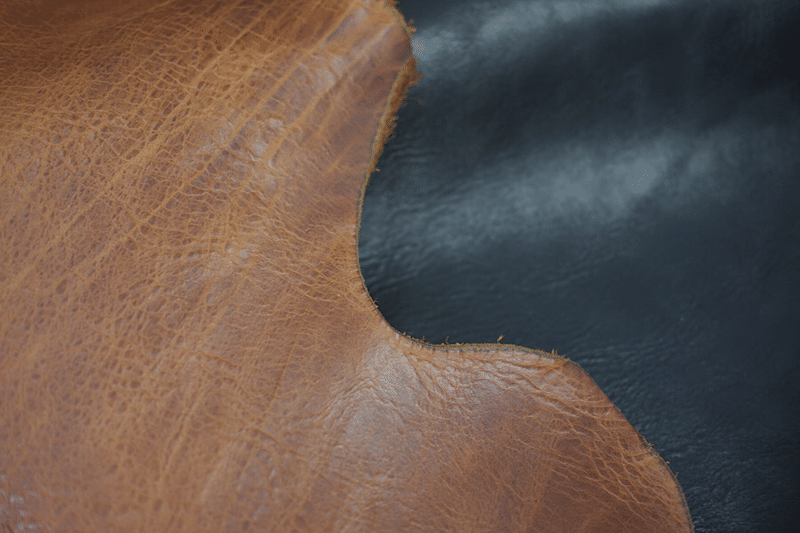

② is tanner. The name probably comes from the tannins used in tanning. Tanning is the process of turning animal skin into leather. Skin can rot and harden. The skin is tanned using tree sap and chemicals to turn it into leather.

(*The above photo was taken at a long-established tannery.)

By the way, before going to the tannery, there is also a rawhide dealer who salts the hide to prevent it from rotting and then hands it over to the tannery.

[Raw leather store] → [Tannery] → [Leather wholesaler] → [Purchase]

This is the usual process, but we are fortunate to be able to purchase from both wholesalers and tanners.

The advantages and disadvantages of buying from a wholesaler

They stock leather, so you can usually get it right away when you need it. However, if the wholesaler runs out of stock, it takes time for the stock to be replenished. They create sample books for standard items, so there seems to be less color variation. When I asked the wholesaler, they said that some types are prone to color variation.

You have to choose from the wholesaler's sample book, and if it doesn't match your image, you have to look for another wholesaler. Even if you are shown sample books from several wholesalers, you may still not be satisfied.

Advantages and disadvantages of purchasing from a tanner

We do not stock leather, so there is a lead time of about one to two months after placing an order. If there is a defect after placing an order, we will have to remake it from the beginning.

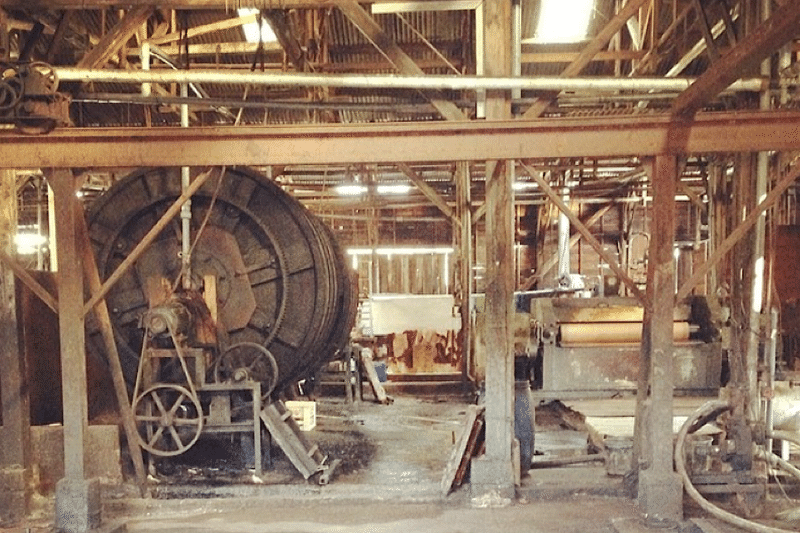

For example, you may be involved in the creation of products using techniques such as waterproof leather using a waterproofing agent or product dyeing. Since several hides are placed in a large wooden barrel called a taiko and turned while being made into leather, it is difficult to purchase just one hide, and you will need to purchase 5 to 10 hides.

You can specify the color and finishing method, so if you have an idea of the leather you want, they will often be happy to discuss it with you. The more processing you do, the higher the price will be.

There is also a greater chance of color variation compared to purchasing from a leather wholesaler.

Since it is not a standard item, you will need to check each time you order the leather and the finished product.

(The above two photos were taken at a private tannery in Himeji about seven years ago.)

Naturally, the purchase price is cheaper than going through a wholesaler. However, when you consider the purchase of multiple items and the delivery time, I think there are good points for both the wholesaler and the tanner.

It's important to use them appropriately

At blueover, we do business with both wholesalers and tanners, and use them appropriately. For example, it is very difficult to make white leather, but we purchase white leather from wholesalers. Our original 2.3mm thick leather is a thickness that is hard to come by, so we made it together with a tanner.

Next, choose a leather supplier based on the characteristics of the shoes or bags you want to make.

We consider the advantages and disadvantages of both options when selecting which supplier to work with for each product. We strive for the best materials and the best products.

<We asked questions about leather>

You often hear the term SDGs. Sustainable Development Goals. Having children, I started thinking about what I could leave for my children's future and what I could do, and I began to have more questions than ever before.

①Are animals really being killed to make leather?

In recent years, fashion brands that don't use fur or leather have been gaining attention due to animal welfare concerns. A leather wholesaler kindly shared their thoughts with us, and we've summarized them below.

While fur and exotic leather are apparently separate items, "leather" is made by tanning the skins of animals that are a by-product of obtaining meat or that have been exterminated as pests. It is said that killing animals that are widely sold as leather products, such as cows and pigs, for the purpose of making leather is punishable by law.

The by-product of the meat production process is the skin, which is tanned into leather and used to its fullest. From that perspective, it seems like an eco-friendly thing to do.

②Is tannin tanning environmentally friendly and chrome tanning harmful?

Tannin tanning is a natural product made from plant-derived ingredients, and certainly does not put a burden on the environment. But what about chrome tanning? When I looked online, I wondered if chromium was harmful, but it turns out that the human body actually contains chromium, and some types are necessary.

Hexavalent chromium is considered harmful, but regulations are very strict in Japan and it cannot be used. Trivalent chromium is used, which is harmless and is actually a mineral necessary for humans!

However, the chrome used in chrome tanning is apparently purified using a purification system, and Himeji and Tochigi, famous for their leather production, have such an amazing purification system that no one can imitate.

In rare cases, some people may experience allergic reactions to both chromium and tannins.

summary

- Leather is produced as a by-product of meat production.

- Chrome tanning is not harmful.

I've always loved leather. I was honestly relieved to hear the answer. I hope to continue clearing up all kinds of misunderstandings and questions, both big and small.

<Summary of tanning process>

We talked about leather yesterday, and we'll continue talking about leather today.

Today we'll be talking about "tannin tanning." Have you ever heard of the word "tanning"? If animal skin is left alone, it will rot and become hard and stiff. By "tanning" it using plant sap and chemicals, it can be turned into leather that is stable and usable.

Vegetable tanning

Tannin tanning is a vegetable-based tanning method that uses tannins (tannins) extracted from plants, which come in a variety of varieties, including persimmon tannins, mimosa, and acacia.

A long time ago, a tanner who I used to work with told me, "Tanned leather is really the same as wood."

The base color is brown, so it has a dull, earthy tone. It is harder than chrome-tanned leather. For leather-soled shoes, thick, tanned leather called Benz is often used.

The stacked heels (those that look like wood) used on leather shoes are made by stacking leather. If you sand them with sandpaper and polish them with a cloth after adding water, they will become shiny, so they really do look like wood.

What is "Furutan"?

It is an abbreviation for full tanned leather. It is leather that is tanned only with plant ingredients, without using any chemicals.

However, just because a leather is tanned with tannins may not mean that no chemicals are used.

In particular, if the leather is not natural (beige), dyes or pigments are used to achieve the color. If these are used, it is not "full tan."

"Furutan" is made only from plant-derived ingredients, so it is a natural product that will return to the earth. It can be eaten after being grilled (please do not try this at home).

The advantages and disadvantages of vegetable-tanned leather

When I was younger, I used to think that tanned leather was the best, but now I think, "Tanned leather is good, but chrome is good, and combination leather is good too!" Everything has its good and bad points.

[Advantages and disadvantages of tanning]

-

Smells good

This is my personal opinion. -

You can enjoy the changes over time (aging) .

The inclusion of oxygen and oil gives it a nice flavor and a glossy amber color. -

Tanning takes time

I hear that the tanning method, which involves placing the leather in a pool containing tanning agents called a pit, takes about two months.

There also seems to be a drum type (where the leather is rotated like a washing machine), which, although slower than chrome tanning, which takes 1 to 5 days, still produces leather in a relatively short time. - Compared to chrome-tanned leather, it stains more easily and is less heat resistant.

- Its elasticity is less than that of chrome, so it is difficult to get used to.

<Chrome tanning, an essential process for shoemaking>

This is a tanning method that uses heavy metal chemicals. It can be tanned in a short period of time, about 1 to 5 days.

That said, the time it takes for the leather to come out of the tannery is almost the same as with vegetable tanning. It takes about one to one and a half months. (Note: If the leather is tanned in a pit tank rather than a drum, it will take longer.)

Maybe it's because most leather in the world is chrome tanned. Maybe there's a waiting list?

Advantages and disadvantages of chrome tanning

-

Easy to process into products

Chrome-tanned leather is more flexible, stretchy, durable, and heat-resistant than vegetable-tanned leather. It is less likely to be damaged during processing, and its softness and stretch make it easier to process. -

Colors can be expressed beautifully

Chrome-tanned leather has a light blue base called wet blue. While leather tanned with tannins tends to have an earthy color, chrome-tanned leather has good dyeability and can reproduce vibrant colors. -

Resistant to aging

I imagine that many customers expect their leather products to age well, but chrome-tanned leather does not exhibit the same lustre or darkening that occurs with aging as vegetable-tanned leather. This means that it requires less care than vegetable-tanned leather, but it may not be enough for those who want to age their leather.

As I wrote before, it doesn't have any impact on the environment.

What about chrome tanning in shoemaking?

If you choose leather as the main material for the upper of your shoes, chrome-tanned leather is likely to be the most popular. It is more resistant to moisture than vegetable tanned leather, so stains may be less noticeable after the product is made.

To make shoes, leather is cut, sewn with a sewing machine, and the finished part called the upper is fitted to a wooden shoe tree, which is then stretched and hammered. The leather is pulled and hammered so much that it's almost cruel. But if it's not done like this, it won't fit the wooden shoe tree properly.

(The photo shows the blueover Goodyear-welded model "PHOLUS.")

If the material is too stiff or doesn't stretch, it's difficult to make shoes, but I once had a case where I made shoes for myself that were so stiff that they hurt my feet.

Also, when it comes to the process of tackling the shoes, the cores that are inserted into the toes and heels need to be melted with heat or chemicals, but chrome-tanned leather is less susceptible to damage, which I find very helpful.

summary

Both vegetable tanning and chrome tanning have their own advantages and disadvantages. At Blueover, we believe it is important to make the most of the individuality of the material when creating products, and this is true for materials other than leather as well. This will lead to products that can be used for a long time.

<Types of leather - Smooth leather>

Leather is called different names depending on its surface finish: smooth leather, velour, nubuck, suede, embossed, shrink, patent leather, etc. Let's start with smooth leather.

Smooth leather

Smooth leather is the most common type of leather. It means "smooth leather" and has no relation to the type of leather, such as cowhide or horsehide. It is classified by the finish.

Therefore, this does not include brushed leathers such as velour, nubuck, and suede, or embossed or shrunk leather. Generally, smooth leather is made by ironing leather that has been chrome-tanned to make it smooth, but even tanned leather and oil leather are considered smooth if the grain surface is smooth. Therefore, even though they are all called smooth leather , the appearance varies depending on the leather finishing method.

For example, let's compare the blueover model.

Examples of models that use smooth leather include Marco and Bob .

The smooth leather used by marco is permeated with waterproofing oil, giving it semi-permanent waterproofing. While you can enjoy the natural look of the leather, it also has a unique luster, resulting in a beautiful leather finish.

The bob cut shows off the white and black beautifully and is made of soft, smooth leather. White is a very difficult color to create, but it is made to look even so that the color and appearance do not change depending on the part of the leather.

By the way, most business shoes are made of smooth leather. To sum up, even though it is the same smooth leather, there are many different ways to finish it depending on the desired look, and the way it looks can be completely different.

<Types of leather - brushed leather>

One of the characteristics of blueover shoes is that they often use leather. They also sometimes use fabrics such as hemp and nylon, but in those cases, they use leather as a combination material. Today, I'd like to talk about brushed leather, which goes well with sneakers.

What is brushed leather?

Brushed leather is leather that has been scraped with sandpaper or other materials to make it fluffy.

That being said, there are many different types, including suede, nubuck, and velour (there are others too, but we won't go into detail here). This time, we'd like to introduce you to suede, nubuck, and velour , which are materials we often use at blueover and which you may have around you.

suede

The most commonly heard type of brushed leather is probably suede . Back when I didn't know much about leather, I thought all brushed leather was suede. (Hehehe.)

Suede is made by raising the underside of relatively small pieces of leather (such as goatskin, sheepskin, or pigskin). Because small pieces of leather have small fibers, even though they are fuzzy, they have a fine, pleasant feel.

(Blueover suede models: Mikey Suede (top), Shorty Suede (bottom))

The leather is thinner than cowhide, so we use it with a lining.

Come to think of it, I once bought a mustard-colored sheep suede jacket at Tomorrowland. It's made from small pieces of leather, so it's lightweight and often used for clothing.

Nubuck

Nubuck is made by sanding the grain (surface) of a large piece of cowhide leather with paper to make it smooth. Among suede, nubuck, and velour, it has the shortest pile and is the most pleasant to the touch, making you want to rub your cheek against it.

It is often used by luxury brands. It certainly feels smoother than other brushed leathers. It has a slight sheen and is made from large pieces of cowhide, so it is thick. It is also often used by blueover.

Recently, the brand's 10th anniversary model, Minna no Mikey, is made of nubuck.

(Blueover nubuck model: Minna no Mikey *Photo is a sample)

Velour

The material we use most often is velour . Velour is a thick piece of leather that has been sanded down with paper or similar.

Also, as mentioned above, suede is small and has fine fibers, but on the other hand, the fibers are large, so the brushed finish is rough and gives it a casual feel.

Velour can be further divided into two types: grained velour and floor velour . Either the surface is grained or not. We love both, but Mikey, which has been around since the launch of the blueover brand, uses floor velour.

(Blueover velour model: Mikey)

We use 2mm thick velour, but it seems to be getting harder to get hold of thick, sturdy velour these days.

What do you think of the brushed leather? Comparing each Mikey makes it easier to see the difference in their impressions. The classic velour Mikey had the most casual and cute impression.

<Waterproof leather: a must-have for rainy days>

It's raining again today. This year, it's not just the rainy season, but the summer as well. The weather is changeable and unpredictable, so you have to be careful with leather shoes and bags.

In times like these, you can rely on "waterproof leather." This is a term we've been hearing a lot lately.

What is waterproof leather?

Previous waterproof leathers were processed on the surface, giving them a flat appearance, which I personally didn't like. I owned leather products because I loved the look of leather, but the surface processing took away that.

I don't remember how many years ago it was, but I was surprised when a tanner showed me the "current waterproof leather." The flatness of the leather is gone, and the texture of the leather itself is still intact. Even if someone said it was waterproof, it was hard to tell. The only way to tell is by whether it repels water.

At Blueover, we use waterproof leather in our Marco and PHOLUS models.

After seeing waterproof leather from a long-established tannery, we worked together to create an "original waterproof leather" that combines beautiful luster with waterproof functionality.

During the tanning process, waterproofing oil is impregnated into the leather itself. The waterproofing function will be maintained as long as the leather fibers remain. This is a material that combines appearance and functionality.

It has become common knowledge that leather is weak against water, but perhaps the time will come when waterproofing of leather will be the norm.

Japan is a country with a lot of rain and unpredictable weather. Waterproof leather is likely to become an increasingly essential item in the future. Its use is likely to expand.

<A blended tanning method that combines the best of both worlds>

As mentioned before, the two most common methods of tanning leather are vegetable tanning and chrome tanning. Today, we will talk about "mixed tanning," a method that combines the best of both these methods.

What is mixed tanning?

Also known as combination tanning, this is a tanning method that combines two or more tanning methods .

It seems that chrome-tanned leather is often processed with tannins. This makes the leather a little harder than leather that is only chrome-tanned, and although it changes over time, it is still enjoyable.

Compared to leather that has been tanned only with tannins, it is softer and more flexible, making it easier to sew and process. It is also more resistant to heat and water than leather that has been tanned only with tannins.

In other words, hybrid tanned leather has the advantages of both chrome tanned and vegetable tanned leather, but it cannot match the advantages of either chrome or vegetable tanned leather.

Compared to chrome, chrome is superior in terms of elasticity, heat resistance, and water resistance, and compared to tannin, tannin is superior in terms of aging and hardness. *The physical properties seem to change depending on the ratio of chrome to tannin in the mixed tanning.

Consider the uses for each

So, how are they actually used?

Vegetable-tanned leather is also used for shoe soles, belts, bag handles, shoulder straps, etc. Vegetable-tanned leather is less likely to stretch, allowing its unique characteristics to be fully utilized.

Chrome tanning is widely used for bags, shoe uppers, car seats, furniture, etc. It seems to be used more often for leather products that require sewing. It also allows for vivid color expression.

Mixed tanning is often used for the same purposes as chrome tanning, such as for bags and shoe uppers. It is also sometimes used in combination with tannins for specific applications.

For example, the 2-way tote bag from WONDER BAGGAGE, another of our brands, is easy to understand; the handle is made from tannin-tanned natural leather, and the bottom part, called the hakama, is made from a mixed tanning method.

Think about it with WONDER BAGGAGE's 2-way tote bag

It would be a problem if the handle stretched with use, so tannin tanning is suitable. For the bottom part, tannin is hard and the leather may crack. Tannin is also prone to staining, so there are concerns about using it in places that may come into contact with the ground. Therefore, we chose a mixed tanning method, which is soft to the touch, easy to process, and less prone to staining than tannin.

The bottom part will also change over time, although it will do so more slowly than the belt part. The bottom part is already soft, so the difference in aging is not noticeable.

Afterword

Ultimately, I believe that each tanning method has its merits, and it is important to understand the advantages of each and incorporate them into the product. By discussing and deciding which material is best to use in consultation with the leather shop and the factory that processes the product, we can create a better product.

<About leather dyeing: dye finish, pigment finish, and everything in between>

I previously wrote about the tanning process, which is the process of turning skins into leather. After tanning, the leather is colored and finished, and then used in various products before being released into the world.

How to finish coloring

The coloring methods can be roughly divided into four categories.

- Unpolished

- Dye finish (including aniline finish)

- Pigment finish

- Semi-aniline finish

Each has its own advantages and disadvantages, and the best parts of each are incorporated into the product.

Unpolished

As the name suggests, this is undyed leather that has not been dyed. Because nothing has been done to it, you can feel the natural texture of the leather.

An easy example to imagine is skin-colored tanned leather. As you use it, you can enjoy the changes that occur over time. The disadvantages are that it is less durable, water-resistant, and heat-resistant. It is prone to staining. It is left in its natural state, like it is without makeup.

When people wear makeup, it blocks UV rays and other things. In that sense, bare skin is like "no makeup." It's easy to understand when you think about it like that. Blueover's Mikey pig lining is bare skin.

Dye finish (including aniline finish)

This is a method of dyeing leather. The dye is dissolved in water or a solvent and used to dye the leather. This not only colors the surface of the leather, but also the inside of the leather, allowing for the expression of a transparent color tone while preserving the leather's unique texture . The surface is finished close to its original state, so the original feel and appearance are preserved . This is a finish that brings out the natural character of leather.

The disadvantages are that it is weak against water and the color fades easily. Also, in the case of smooth leather, if the leather is not clean, the original scratches and patterns of the leather will be noticeable. Dye finishing is not often used for large cattle such as steers, as the leather develops over time through fighting, insect bites, and other life-long experiences. It is often used for smaller cattle such as calf and kip.

However, it is used for the outer leather of blueover's classic Mikey. Mikey is velour. Since it is brushed leather, it is finished only with dye.

Aniline (synthetic dye) finish is one type of dye finish. There are also other types of dyes, such as natural dyes made from plants and casein (a protein found in milk).

Aniline is the most commonly used dye because it dyes both tanned and chrome-tanned leather well. That's why you often hear the term "aniline finish."

Pigment finish

It is used to coat leather to hide scratches and stains. After applying the pigment, the leather can be given a uniform finish in color and texture, and vibrant colors can be expressed.

The disadvantage is that some leathers that are only made with pigments can easily peel off when scratched, making the scratches more noticeable. If too much pigment is used, it becomes like a thick layer of makeup, which reduces the leather's natural character.

There are also advantages. Because it is a film, it is durable. It is quick and easy to care for. The color does not easily fade even when it gets wet.

Semi-aniline finish

This finishing method combines the best of aniline and pigment finishes . It uses mainly dye and a small amount of pigment to hide scratches and stains on the leather. It is also very difficult to achieve the desired color using only dye, so pigment is also used for the final color matching. Even if the desired color is achieved when it is liquid, it may turn out to be different once it has soaked into the leather.

Since there is only a small amount of pigment, the leather retains its natural texture and has a glossy, transparent appearance.

Although it is inferior to the natural finish or dye finish, you can enjoy the beautiful changes that occur over time. It is said that most leather finishes are made this way. It is also resistant to fading, and is used for car seats, sofas, etc.

At blueover, the bob cut is a good example.

White is difficult to achieve with dye alone, and is often created using only pigments. The smooth leather used in "Obappa" is semi-aniline finished. A thin layer of pigment is applied to create a beautiful white, and because the dye is the main ingredient, the leather has a glossy, transparent finish, allowing you to enjoy the natural look of the leather.

A side note

I heard from a tanner that while rubber erasers or sand erasers are sometimes used to remove stains from leather, bread is also recommended. It doesn't scratch the surface of the leather as much as an eraser, so it's less likely to cause discoloration.

It may end up covered in crumbs, but give it a try.

<About shoe leather lining>

Have you ever heard of the word "lining"? The word's origin is liner, and when I looked it up, I found that it means the following:

Liner explanation 1: In baseball, a ball that flies low and straight through the air. A line drive.

2. Regular ships, regular passenger planes, or regular long-distance trains.

3. The removable lining of a coat, etc. Also, a protective lining or covering.

4. A tool for drawing lines. "Eyeliner"

<From goo Japanese dictionary>

The lining we are referring to here is the part that lines the upper of the shoe, so we are referring to ③ ``protective lining.''

In the photo below, the white part that comes into contact with your skin when your foot is inside (the back of the blue leather) is the lining. Not only does it provide protection, it also absorbs sweat from your feet, which affects the environment inside the shoe.

The lining used by blueover

We would like to introduce the linings we use.

- Pig lining

- Cow lining

- fabric

Pig lining

It is thin, light, and resistant to friction. It is also highly breathable, so it is often used as shoe lining.

In Japan, pigskin is a type of leather that can be obtained 100% self-sufficiently, making it relatively inexpensive. Its color is highly reproducible, making it suitable for a wide range of ages, from men to women.

At blueover , we use a natural finish for the back of the waist in styles like Mikey, Bob, and SHORTY. The Bob and SHORTY styles are light beige, while Mikey is white.

Lining stores dislike "whitish colors." They say they turn yellow if stored, making them unsellable, so there are few stores that stock them. I searched and searched and finally found a store that stocks both light beige and white, and I'm happy to purchase them from them.

Cow lining

It is thicker than pig lining. It is strong, breathable, moisture-wicking, and durable. It has small pores and looks good, so it is also used for high-end shoes.

At blueover , we originally used unpolished cowhide lining, but the color was uneven, so we now use leather that has been polished and then lightly lacquered. We created the camel color together with a lining maker in Tokyo. We use this in our McKay-made Marco and Goodyear PHOLUS models.

The insoles of these two models are cup insoles made of the same material.

fabric

Some models use functional materials. They are highly breathable, quick-drying, and many also have antibacterial and disinfecting properties. They also have a sporty look, giving them a sneaker-like feel. They also break into your feet faster than shoes with leather linings.

At blueover, we use urethane on knit or nonwoven nylon fabric. We use it on the mikey and SHORTY shoes, but on the mikey, it's on the sole of the toe, so it may be hard to tell at first glance.

Afterword

In Japanese shoes, the lining is made of a variety of materials, including synthetic leather, artificial leather, fabric, and more, in addition to leather and fabric. Since it is not easily visible, many people may not pay much attention to it when purchasing shoes.

However, often the original purpose is not achieved.

They protect your feet, absorb sweat, and keep your shoes in a good condition.

If you keep this in mind and pay a little attention to the lining when purchasing your shoes, you will be able to enjoy them for a long time.