blueover's story #03 About the manufacturing process

|

ZUCCO Blueover's sample craftsman. He creates shoes by hand, from making patterns to sewing and shoemaking. He also arranges for factories and materials. @blueover_zucco |

This series is a compilation of several posts I wrote on Note in an attempt to explain my work - that is, making shoes - in as easy-to-understand a way as possible.

<About the popular cemented manufacturing method>

Hello, this is Zucco from the blueover team.

Today I would like to talk about the manufacturing process of shoes.

How are shoes made?

When you hear the term "manufacturing method," many of you may be wondering, "What does that mean?" There are many methods for attaching shoe soles, and each method has its own name.

There are many types of shoes, such as cemented, McKay, Goodyear, stitch-down, vulcanized, opanke, moccasins, etc. They can be broadly categorized into "sewn sole" and "non-sewn sole" methods.

The majority of shoes are made using a method that does not involve sewing the soles (in this case, cemented and vulcanized).

Today, I would like to briefly introduce the most popular manufacturing method, the cemented method .

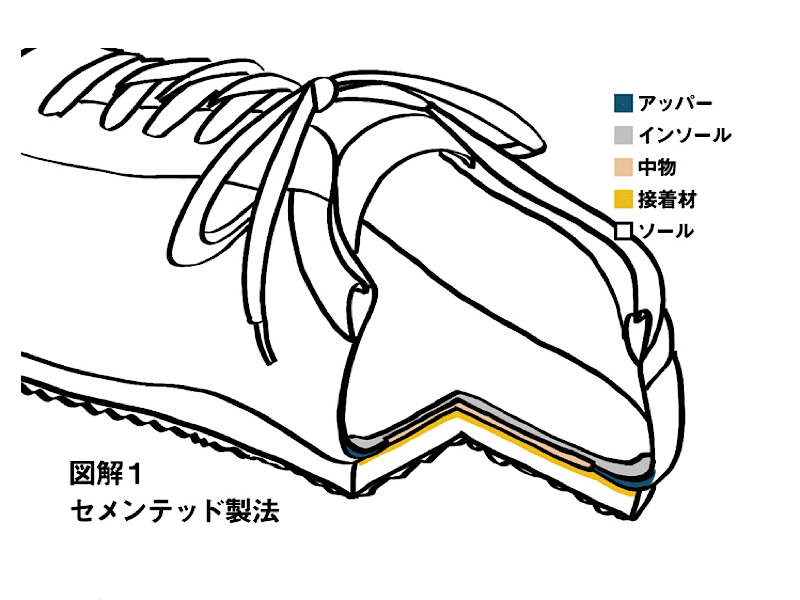

Cemented manufacturing method

Regardless of the type of shoe, most shoes are now made using the cemented method. For women's pumps, the thin soles make the shoes look delicate and beautiful, so I think that almost 99% are made using the cemented method (this is also my personal opinion).

At blueover, we use this style on ``Mikey,'' ``SHORTY TR.'', ``kopori,'' and ``bob cut.''

History of the Cemented Process

It seems to have been invented in the 1850s, and a machine for attaching the sole was developed in the late 1920s. (I wonder if the machine for attaching the sole is a crimping machine?)

When I heard it was 1850, I didn't really understand, so I looked it up and found out it was during the Edo period, when Perry came to Japan! The Black Ships. That makes me think, I see! It's been around that long.

(Mr. Perry has no connection to the Cemented Process.)

Until then, shoes required sewing on the soles, and it took a very long time to make them.

(The McKay machine was invented in 1858 and the Goodyear machine in 1874, so considering the timeline, it can be assumed that the bottom stitching was done by hand.)

After World War II, demand for shoes increased. Compared to previous shoemaking methods, cemented shoes could be mass-produced and developed dramatically with advances in adhesives .

The relationship between production method and design

The upper and sole are glued together and then pressed together. This is a very simple process, allowing us to produce products of consistent quality.

When sewing the bottom, a large machine is used to sew a thick needle up and down, making a loud noise, and a thick thread is threaded through it, so the material needs to be thick enough to withstand that .

The cemented method does not require sewing the bottom, so thick needles and threads are not required and a thin and lightweight sole can be attached.

For this reason, it is not subject to design restrictions and is used in a wide range of shoes, from cheap shoes to expensive brand-name shoes.

Can it be repaired?

The adhesive used in cemented shoes is very strong. (However, when I was working at a repair shop, I also saw shoes with the soles peeling off due to deterioration of the adhesive.)

Blueover's current models are treated with a treatment agent before the adhesive is applied, and a hardener called Desmodur is mixed into the adhesive to make the bond even stronger.

Death Module [Features]

The one-component type has the effect of increasing adhesive performance on materials that are difficult to bond.

(1) Strengthened adhesive strength (2) Improved heat resistance

(3) Improved water resistance (4) Improved oil resistance

(5) Stability after adhesion

<Quote: Mamoru Online Shop >

When we repair our shoes, it's not because the sole has come off, but because our customers have loved them and the sole has worn down and they still want to wear them. (Thank you!)

Because the adhesive is strong, it is not easy to remove the sole. The sole is ground down with a grinder, taking care not to damage the upper. The worn out sole and old adhesive are carefully removed, the wooden shoe tree is reinserted, and the shoe is once again prepped in the same way as it was during production, and then glue is applied (mixed with Desmo, of course) and pressed together.

Until now, we have not recommended repairs because we believe that cemented models are not suitable for all-soles.

There are two reasons.

- The stress placed on the upper when grinding or re-inserting the last may lead to tearing.

- Cemented shoes have no sewn soles, so the upper is not fixed to the insole, and removing the sole entirely may change the feel of the shoe.

Of course, we are working as carefully as possible. We would like to return the item in its current condition, but the possibility of the above happening is not zero.

However, recently, we have been fortunate to hear from customers who say, "I still want you to repair it!" So, after consulting with the factory and confirming and obtaining the customer's consent for the two reasons above, we have decided to proceed with the repair.

(This is a very recent issue, so we apologize to everyone who has not recommended this product until now. If you would like to have it repaired, please contact us via the repair inquiry form on this website .)

Other brands may or may not be able to repair it. Cemented tires can generally be repaired, but the procedures vary by brand.

This is the answer.

Afterword

What did you think? Personally, the history section made a big impact on me. I learned that it's older than the sole stitchers McKay and Goodyear.

A little anecdote from the factory: apparently shoe factories in the Kansai region mix Desmo into their adhesives, but shoe factories in the Kanto region don't (I don't know if this is true or not, as I've never worked in a Kanto factory, and I apologize if I'm wrong).

The reason is that factories in the Kanto region make shoes with the assumption that they will be repaired. If shoes are made without a desmo, it seems that the soles can be removed without scraping off the entire bottom if the proper treatment is done.

<About the lightweight bottom stitching and McKay method>

I always write in the middle of the night. It's quiet and easy to concentrate. Today's post will be a continuation of the recipe from the other day.

What is the McKay method?

This is a manufacturing method in which the upper, insole, and outsole are sewn together from inside the shoe using a large sewing machine.

Some people in the industry call it "Aryan."

*If you say Arian, people might mistake you for someone in the shoe industry!

There is an insole inside the shoe, right? Beneath the insole is a part called the midsole, and in shoes made using the McKay method, you can see the seams on the midsole.

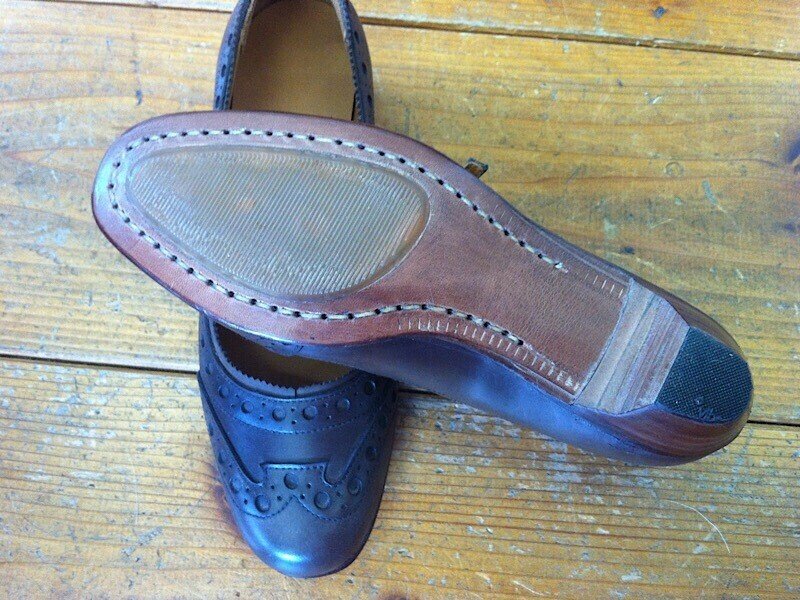

(The photo above shows the insole removed and the midsole exposed. In the case of McKay construction, the stitching is visible.)

In contrast to the method of sewing around the outside of the shoe, this method of sole attachment results in a seam that runs all the way around the inside of the shoe.

History of the McKay Method

The machine was developed in the United States in 1858, after the cemented method that I talked about the other day.

The original technique itself seems to have originated in Italy. Indeed, Italian shoes tend to be made using the McKay method, which has a single sole that is light, flexible, and has good rebound.

Advantages and disadvantages of the McKay method

merit

Since there is no need to sew the welt, it is possible to make the welt thinner and narrower. *Welt is the part that extends beyond the perimeter of the shoe upper.

There are few design restrictions and the outsole can be sewn from a single piece, making for a light and comfortable fit.

(The photo shows shoes I made a long time ago, before I joined blueover.)

Disadvantages

When repairing an all-sole (re-soling), the stitching on the bottom needs to be untied. The thread penetrates through the insole, and the repair requires re-stitching.

Each repair will damage the insole, so it is said that the soles of shoes made using the McKay method can only be replaced once or twice.

If you buy McKay shoes, it's a good idea to have them re-soled at a repair shop! This will prevent the stitching on the bottom from breaking and make them last longer!

(However, wearing them with the leather soles will give you better bounce. It's up to you!)

(We recommend Vibram. 2mm half soles are common, but 1mm ones are also available. The rubber compound makes them stronger than 2mm.)

How to use the McKay method in blueover

At Blueover, we use the McKay method for our "Marco" model. This popular model has a neat appearance and can be worn both on and off the job.

At marco, we have adopted the McKay method to make it easier to repair the entire sole.

As mentioned earlier, these shoes are not suitable for repair, but at blueover we prepare a part called an "Ainaka" and after fitting the shoe, we attach the upper, insole and "Ainaka" and sew them together using the McKay method.

Finally, the cup-shaped outsole is glued together using the cemented method.

The progression is ① McKay → ② Cemented .

This way, when repairing by replacing the sole, it is possible to replace only the outsole part that is cemented together (②).

There is no need to untie the stitching on the "Ainaka" and the insole. To ensure that you can enjoy your shoes for a long time, we use a different McKay method than usual.

The outsole is made of EVA, so it doesn't interfere with the lightness of the McKay.

Afterword

What do you think? Was the explanation easy to understand?

If you search, you will find many brands such as McKay and Goodyear. If you want to know more, please try searching.

<About the coveted Goodyear welt manufacturing method>

This is a continuation of the previous two articles. Today I would like to talk about the manufacturing method (attaching the sole).

What is the Goodyear welt method?

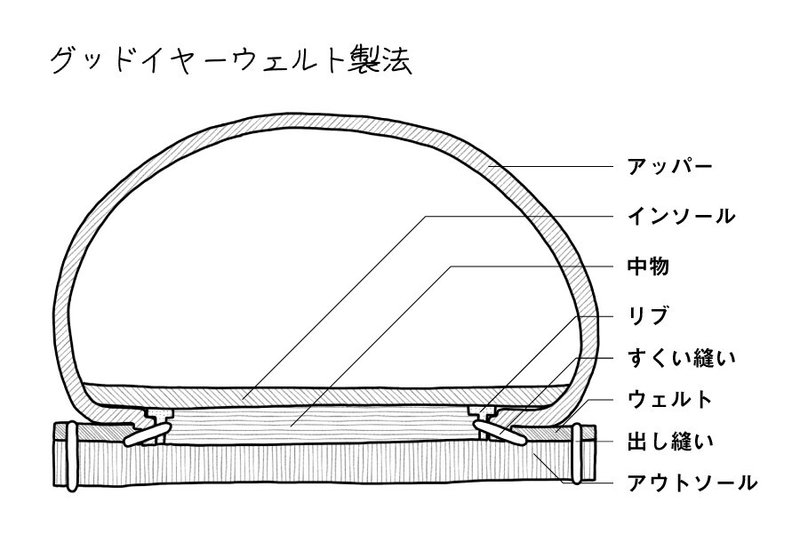

Goodyear is a well-known method of sewing the soles of shoes. It requires two machine-made stitches: a blind stitch and a topstitch.

① Fabric tape (rib) is glued around the insole, and then this is sewn together with the upper and welt by machine (overlock stitch) .

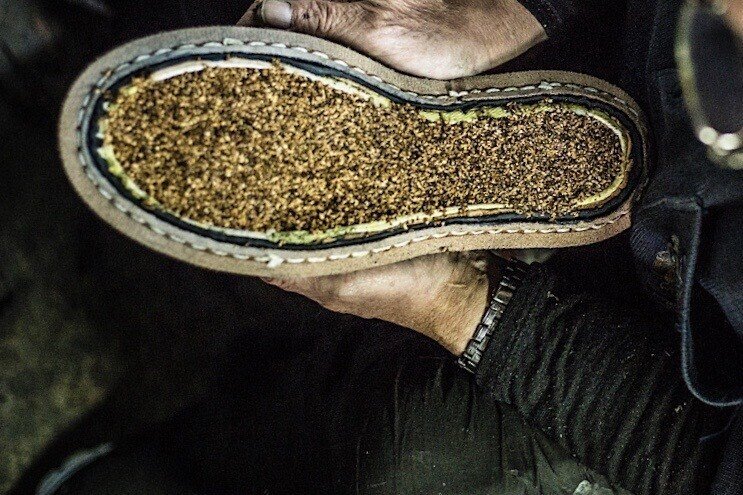

(The photo shows the cork filling after the blind stitching.)

② Filling materials such as leather, felt, or cork are placed at the bottom of the insole, and the welt and outsole are sewn together by machine (topstitching) to complete the shoe.

The materials used are often thick tanned insoles and soles called bends and shoulders, and the preparation is time-consuming, which is why they tend to be expensive.

*In the previous McKay shoes, the stitching on the insole was visible, but in Goodyear shoes, the stitching is on the rib, so no stitching is visible on the insole itself.

History of the Goodyear Welt

This manufacturing method was invented in the United States by Charles Goodyear Jr. between 1874 and 1879, based on the hand-sewn welted method.

Hand sewing is the process of sewing the above item ① by hand.

Rather than attaching ribs to the insole, the insole itself is often processed using a leather knife, etc. It is easy to imagine that this must have taken a very long time.

(The photo shows the hand-sewn welt construction used in the early PHOLUS models.)

The development of Goodyear's machinery paved the way for shoemaking that made extensive use of machinery.

Advantages and disadvantages of the Goodyear welt method

merit

If you need to repair the sole, you can remove the overstitching and it won't affect the upper. This means you can replace the sole without touching the understitching. You can also use the shoe for a long time.

As you wear them, the cork and felt stuffed into the gaps between the insole, welt and outsole, as well as the thick leather insole and sole itself, will slowly sink in and conform to the wearer's feet.

Once you get used to them, they are incredibly comfortable to wear! (This is also my personal opinion.) This manufacturing method that creates a thick sole is apparently often used in the UK, where it rains a lot, so they definitely give off the impression of being British shoes.

Disadvantages

As mentioned above, it takes time and money for materials. It is often expensive. The machine is difficult to operate, and there are few craftsmen who can use it. There are many people who can do hand sawing but cannot do Goodyear sawing.

Because they use thick insoles and soles, they feel stiff when you first put them on. They don't bounce as well as McKays, but that makes them more durable.

It will take a little time to get used to it.

However, everyone has different preferences. I like the firmness of Goodyear and the way it breaks in as you wear it. I also like the flexibility and ease of use of McKay.

Replacing shoe soles

Even if you are told that you can repair it by undoing the stitching, replacing the sole is expensive.

As with McKay, it may be a good idea to have a half sole attached when you purchase.

In this case, Goodyear does not have good flexibility, so applying a half sole may make the shoe feel even stiffer, so please take this into consideration when deciding whether to apply one.

blueover Goodyear welt model

At blueover, we use Goodyear tires in our "PHOLUS" model. "PHOLUS" was born thanks to the cooperation of the factory that has produced various models over the past 10 years.

After steps 1 and 2, we attach an EVA outsole, typical of blueover.

The EVA sole provides cushioning, and although it is Goodyear welted, it is not too stiff even when you first walk in it. However, you can still feel the durability of Goodyear, and it provides a firm feel underfoot.

As with Marco , which uses McKay, repairs can also be made by replacing only the outsole, making repairs easy.

Afterword

The Goodyear welt consists of two large bottom stitches .

Before I started working with shoes, I was confused and didn't really understand how to sew soles. That's why I include a lot of photos.

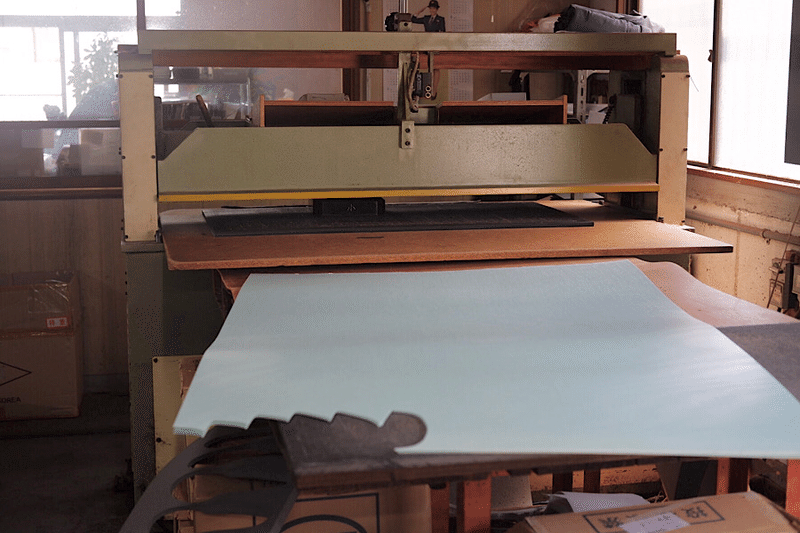

I hope you were able to get a feel for the atmosphere of a shoe factory. Although machines are used, there are many parts that rely on the skill of human hands, and shoes are made by human hands.

<The core material of the toe and heel>

Hello, this is Zucco from the blueover team.

Feel your shoes. If the toe and heel are hard, then the shoes have a core material called a "toe cap" in the toe area and a "counter" in the heel area. It may be hard to tell at first glance, but it is sealed between the outer leather and the inner leather (lining).

Toecap

By inserting a toe cap, the shape of the shoe tree is hardened, so the shape is properly expressed in the shoe and it prevents the shoe from losing its shape. It also protects the toes.

counter

It protects the heel and supports the arch of the foot. It also provides stability when walking. It also prevents the shoes from losing their shape.

If you walk on your heels or put on your shoes without a shoehorn, the counter may get crushed. Once crushed, it will not return to its original shape, and the broken counter inside the shoe may rub against your foot and cause pain, so be careful!

material

There are a variety of materials used for the toecap and counter.

When I was making shoes myself, I used hard toe caps that would soften in a solvent like paint thinner. For countertops, I used leather skiving mats or leather boats purchased from a wholesaler.

I softened it in water, cut it to a size that would fit inside the shoes I made, and then attached it with white glue.

*It is still sometimes used when creating samples.

Our current production method for shoes is called "hot melt." When exposed to high heat, the material softens and when cooled, it hardens. While softened by heat, it is pulled along the wooden last, and retains the shape of the last.

Most shoes made in Japan are made with this "hot melt" adhesive. It is less likely to tear than leather countertops, and when making shoes, it is easier to work with the back part , which determines the heel height, and allows for efficient and smooth fitting work.

If you are mass-producing a certain number of pairs, I recommend hot melt. You will need to create a die, but once you order it from a materials store, they can make it fairly quickly.

This year, I replaced the toe cap and counter. I'd like to write about that next.

<The story of searching for core material>

We explained that the toe area contains a core material called a "toe cap" and the heel area contains a core material called a "counter."

I recently replaced the core material for each piece, so today I'd like to talk about that.

Why it's new

In fact, this spring, the core material of Blueover's classic model Mikey has been updated.

You might think, "We've been using the brand for 10 years now without any problems, so why change it?" In fact, there was no need to change it in terms of quality. However, because our supplier went out of business, we had to find a new supplier.

Finding a factory

I was looking for a new factory, so I contacted Nakashikiya, a company I hadn't worked with for over five years, to get an introduction.

We were introduced to a Kobe company that handles toe caps and counters because they have a long-standing relationship with them.

When I was searching for a factory and materials, the most important thing for me was to make sure that the product was not too different from the current Mikey. This is because there have been no problems for 10 years and we have received feedback that customers have been using it for a long time.

We were shown several material samples from the other party, and although the counter looked good, the toe cap felt too soft and was rejected.

Next, I contacted the factory that makes the current Blueover insoles. Here, I was also able to see some of the materials.

Try making a prototype

We have gathered several toe caps and counters. Even if we have our eye on something that looks good, we cannot immediately mass-produce it. We will narrow down the candidates to two toe caps and two counters and then actually make shoes out of them.

Even if the finished product is good, we cannot adopt it if there are inefficiencies in the sewing, finishing, or other processes at each factory, so we interview the factories and also look at the final product.

And the mission to create a new material was a success.

Afterword

Shoemaking involves a lot of work and materials being placed in places that cannot be seen. Replacing the toe cap and counter in this case may seem simple at first glance, but it also requires sewing and finishing, so it was a mission that took more than a month.

Change in order to stay the same.

"New, unchanged."