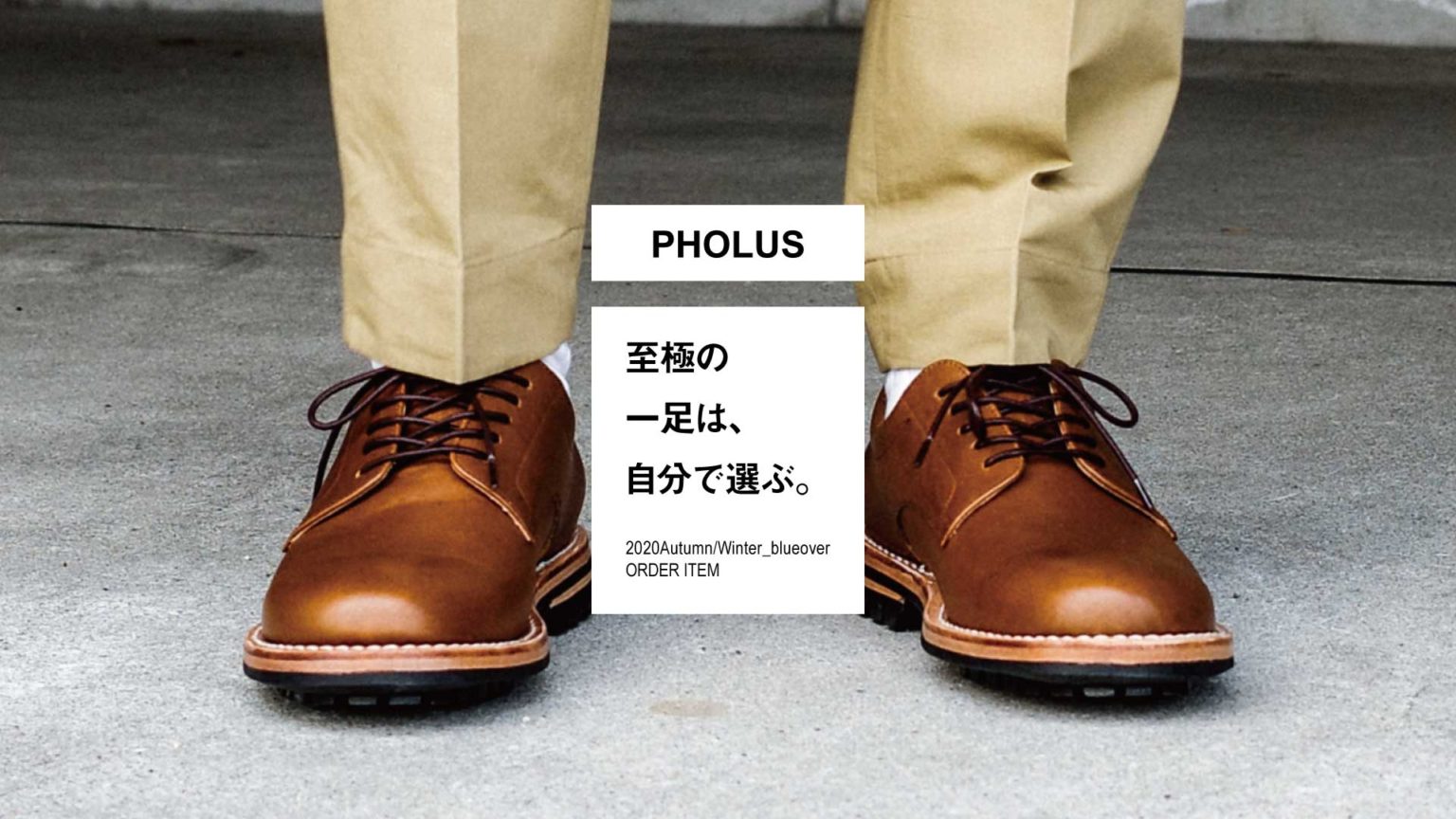

To celebrate the start of Shoemaking.

2021 is Blue Over's 10th anniversary year. Several projects are underway to commemorate the 10th anniversary.

One of these is ``Shoemaking'', a content that introduces ``Shoe-Wotsukuru''.

This time, we will talk about the reason why we started this content, the production background of Blue Over, and what we really want to convey through this new content.

We interviewed designer Watari. The interviewer is Egawa, a staff member.

EgawaLet's hear about the shoemaking introduction content "Shoemaking" that was released the other day. thank you

Watari

please!

Egawa

When creating the content, I realized that there aren't many other sneaker sites that introduce this kind of shoe making.

Watari

is not it. The brand Blue Over, which we have been working on, has been around for almost 10 years, and a lot of things have happened and I'm thinking about it.

Once again, what should I do now?

Egawa

The 10th anniversary is the perfect time to take a fresh look.

Watari

That's right

Egawa

It's also important to make and sell shoes domestically. In the first place, I wanted to explain the basics of shoe making in a little more detail and archive it, so I'd like to start by introducing the shoe making tools.

Nowadays, we are overflowing with all kinds of information, and it's easy to get what you want to know right away, right?

Watari

It's true that if you do a search, you can find most things.

Egawa

But surprisingly, there aren't any sites that focus on and explain the process of making shoes. So, I thought it would be great if people who are interested in shoes could become attached to the shoes they own through this site, or become interested in or involved in shoe-making. I decided to try it

Egawa

I see.

It's a service for Blue Over fans, and you also want it to serve as a guide for people who are interested in making shoes.

Watari

Hmm. It's aimed at our fans, but it's also aimed at a wider audience.

Well, we'll start with content related to our daily lives, but eventually we'll also introduce other manufacturing methods other than the ones we use.

Egawa

So, is it like vulcanized?

Watari

That's one thing.

People who are interested in shoes come here through these various entrances, learn a lot, and think, ``I want to try making shoes!'' I would be happy if it could be an opportunity like that.

Egawa

Regardless of the brand, let's expand the door to shoe making! What does that mean?

Now that I think about it, part of the Struct storefront is now a small shoe factory where samples are made.

Watari

Well, probably around the end of last year.

Egawa

Making things in a way that customers can see seems to be similar to the content featured in this article on shoemaking tools.

Watari

That's certainly true.

The reason why I moved the sample production location to Struct was partly because I moved and I no longer had the space in my office (lol).

Egawa

That's right (lol)

Watari

But I think it's nice to have an atelier behind the counter where samples are made, as it feels like it's exactly what's happening right now.

I feel that way. In fact, there are still samples lying around that will be unveiled first.

Egawa

Come to think of it, the first surprise I felt when I joined the Blue Over brand was that Azuma-san had handcrafted sneaker samples.

I had the impression that sneakers are mass-produced in factories, so I was surprised and wondered, "They can be handmade!?"

Watari

By the way, how did you think you could do it?

Egawa

The image in my head at the time was something like what I saw on a TV show...

For example, I had the image of semi-finished products like mayonnaise and canned goods flowing down the line and being completed in the blink of an eye.

Watari

Shoes are like mayonnaise or canned food! ! !

The idea was that the arm of a huge machine would move and it would be able to create something even without a human being, right?

Egawa

It's funny when I think back on it, but yeah (lol)

I only had very automatic images from factory tours I went to when I was a student, TV shows, etc.

Watari

I see

Egawa

That's why I was so surprised to see Azuma-san making samples by hand...Customers can experience this surprise at the Struct store. I think it's great that the atelier is attached to Struct.

Azuma: Blue Over brand member and shoe craftsman. The first samples of shoes are made at the atelier attached to Struct based on Watari's designs. The shoemaking tools introduced this time are the tools Azuma actually uses.

Egawa

And actually, contrary to my initial expectations, shoe factories are very analogue.

Watari

Even if you make shoes all at once, there are many different types.

The factories of mega-brands must seem mechanical. The molded sole and knitted upper are truly high-tech.

Our brand is right in the middle of "analogue." Upper and sole are analog

Egawa

What's a little confusing here is that although the samples made in the atelier in Struct's stores are close to being handmade, the work done at the factory where Blue Over is mass produced is not as "handmade" as handcrafted. Is not it

Watari

I agree.

Even though it's analog, it doesn't mean that everything is done by hand in order to efficiently produce a certain number of products in a factory.

It's true that I want to convey that nuance, so eventually I'd like to feature factory machinery as well.

Egawa

Actually, there is a gradation in whether it is handmade or machine made...

Watari

Yeah. In some cases, machines are operated by humans rather than fully automated.

1: Everything is made by machine

2: Manufactured by people using machines

3: Using machines (manual work)

In terms of these three stages, Blue Over is the second, "made by people using machines."

Egawa

Isn't it?

Watari

If you count sewing machines as machines, I don't think there are many sewn products in Japan that are entirely handmade.

Use tools, use machines. There's no doubt that all of this is being manipulated by people.

Egawa

We must not forget that people are making it.

Mass-produced items can be replaced over and over again, creating the illusion that they are forever.

Blue Over is particularly far from that kind of property, so when I explained it to the customer, I was conscious of making sure that those details were clearly conveyed.

Watari

That's true. There are people who make our things right next to us.

Of course, for those who create things, there is no eternity or change, time is limited, and each person has their own daily life.

Shoes are being made inside it.

But it's hard to understand if you just look at the finished product.

Egawa

What happens during production is usually a black box.

This time, by first introducing the tools, we hope that those who come across Blue Over on the web can imagine the process of making them and the time it takes, and appreciate the inherent value of the product. I hope you can feel it

WatariI hope that by making people aware of these things, the way they interact with things will become more positive and enriching.

Click the image above to go to the “Shoe Making” content page.

Also, if you have any questions or want to know about shoe making, please contact us !